Découvrez 9 cas où nos tests sont recommandés :

Répondre aux obligations légales

Trouver l’origine d’un désamorçage

L’origine peut être multiple : clapet anti-retour défectueux, tuyauterie d’aspiration non étanche, prise d’air à la pompe,…

Localiser une fuite au gaz traceur

Vous souhaitez connaître l’endroit exact d’une fuite afin de remettre en service la distribution le plus rapidement possible ?

Vous avez la certitude que telle tuyauterie présente une fuite dans sa portion enterrée ou inaccessible, et vous souhaitez localiser précisément l’endroit problématique pour limiter les coûts de réparations et les embarras liés aux travaux …

Test indépendant des réservoirs et tuyauteries neufs

En 2018, 78% des stations-services avec de nouveaux réservoirs et tuyauteries présentaient au moins 1 défaut d’étanchéité sur leur paroi interne.

- Soyez assuré de l’étanchéité de vos installations dès leur mise en service avec un contrôle indépendant et fiable.

- Vos tuyauteries sont en double paroi ? Nous pouvons vous assurer, par une méthode brevetée et rapide si leur étanchéité est complète et sur les 2 parois.

Votre offre technique et budgétaire

Savoir pourquoi un détecteur de fuite est en alarme

- L’alarme du détecteur de fuite de votre réservoir double paroi est en alarme et vous souhaitez en connaître la raison.

- Cette alarme n’est pas forcément due à un défaut d’étanchéité de la cuve.

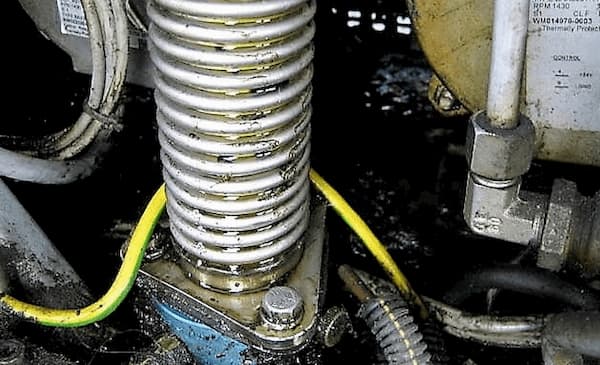

ITM a développé des équipements de contrôle spécifiques et une approche structurée afin d’expertiser de façon indépendante l’étanchéité de l’espace interstitiel ainsi que les autres accessoires composant le système de détection de fuite. Grâce à cette expertise, ITM est en mesure d’identifier l’élément non étanche (enveloppe interne, enveloppe externe, tuyau de liaison, …)

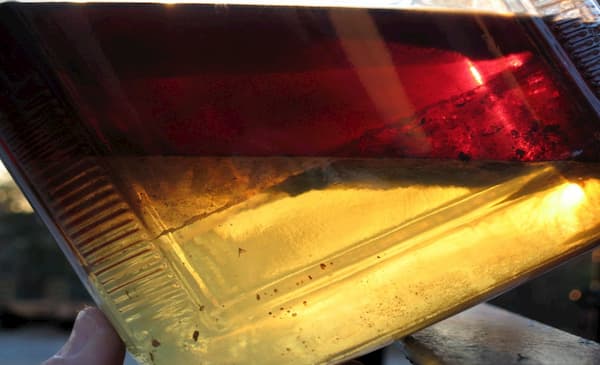

Eau dans le carburant ?

Servir de l’eau à ses clients à la place du carburant risque d’égratigner votre image de marque et ce, pendant longtemps.

ITM expertise votre installation et localise le problème.

Connaître l'origine d'une pollution

L’origine d’une pollution peut être multiple : déversement accidentel lors d’opération de remplissage, raccord tuyauterie qui suinte, canalisation percée, pollution historique, …

Vous souhaitez écarter ou confirmer l’hypothèse d’une fuite sur une installation hydrocarbure ?

Pourquoi des écarts de stock ?

Vos relevés indiquent des écarts et vous avez déjà fait contrôler vos mesureurs.

Vous souhaitez écarter ou confirmer une hypothèse de vol, erreur de réconciliation, jaugeage imprécis, fuite,…

Déterminer d’où proviennent des vapeurs d’essence

Une accumulation de vapeurs d’essence peut amener des risques multiples (explosion, intoxication respiratoire). Nous avons la possibilité de localiser de façon précise l’élément non étanche sur votre installation à l’origine de ces vapeurs d’essence.

Votre offre technique et budgétaire

Nos clients sont principalement des groupes pétroliers, des organismes d'inspections, des industries mais aussi des indépendants.